The manufacturing industry in Australia has had the luxury of reliable supply of primary energy whether it is electricity or natural gas. The recent fires across Australia threatened to disrupt electricity distribution networks as well as some of power generation plants. The power generation and supply has already been under enough strain and it is expected to get worse as we have encounter more adverse weather conditions in the future.

There is an ongoing debate on the effects of green house on global environment and the industry. When we consider that nearly 80% of electricity is generated in Australia through fossil fuels – coal and natural gas, the increasing focus on reduction of carbon emissions and sustainability will only make it harder and more expensive for Australian industry to source its energy needs.

Electricty, Gas, Water & Waste Services Electricity Generation

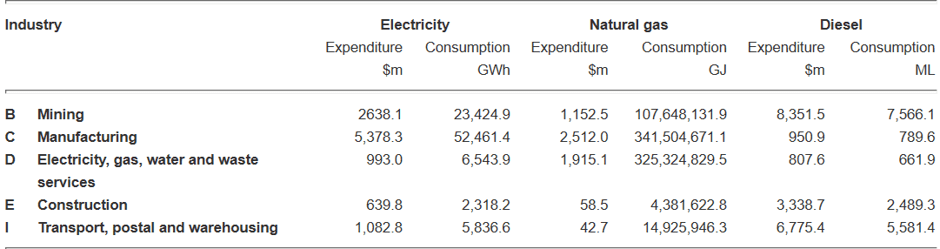

For as long manufacturing industry in Australia has considered energy costs as fixed costs of business & previously these costs used to be less volatile due to long term supply contracts. However, in the recent times, there has been greater volatility in energy supply costs which have resulted in higher cost pressures. The energy costs for most manufacturers tend to range between ~ 2 – 4.5% of the cost of sales although they can vary for different industry segments.

It is time for manufacturing Industry in Australia to focus on energy conservation and optimum utilisation of resources. Such is brought about by potential energy supplies unreliability, escalating costs, greenhouse emissions and environmental charges by electricity generation and distribution companies.

The manufacturing industry in Australia in general has quite a strong focus on preventive maintenance across its manufacturing plants in comparison to many other industrialised economies. This in turn creates the perception that plants are operating optimally and there is no wastage of energy across the plant.

The inference is only partly true since majority of preventive maintenance is aimed at ensuring that the plants operate without any unscheduled break downs. However, the maintenance services may not necessarily focus on the energy efficiency of plant & equipment, particularly utility systems.

The inefficiencies in energy usage can be due to incorrect selection of equipment, aging, process related issues, production practices, narrow maintenance focus or even due to lack of knowledge.

Plant upgrades and replacement of major production equipment can be quite cost prohibitive. However, you should be asking some simple questions in relation to energy consumed within your plant –

- Do you have the appropriate set up of main electrical transformers or are you incurring significant fixed electrical losses?

- Do some of production machines need to remain in “ready” state when they are not in production mode?

- If your plant uses steam boilers, are they correctly sized, properly set up and optimally utilised?

- If your plant uses cooling or process water, is the distribution system suitably automated so that water supplies when an equipment is not in production, is switched off. This would reduce thermal and electrical load on the system. The automation does not need to be cost prohibitive.

- If you use gas burners for thermal oil heating, solvent destruction systems or similar applications, do you get the burner systems serviced regularly? Even if yes, do you also undertake stack gas testing not just from emissions compliance reasons but also to check the quality of gas combustion. We regularly find incorrect gas and combustion air ratios resulting in ongoing gas and energy wastages.

- When did you last check the extent of air leakages from your compressed air network? Quite easy to do and the results could shock you. In one of our recent FAD tests, we found 37% leakage – that is the extent of energy going to waste?

- Air and water chillers – are they energy efficient or low capital investments? You may be surprised with the payback on some of newer, energy efficient units. Replacement or in some cases upgrade of some of the older units with more efficient units can in some cases be a very wise investment.

- Do the lights and air conditioning remain on over the weekend or on non – production days in the plant, warehouses or offices?